K/KA/KAF37-187 Series Bevel Helical Gear Reducer for Agitator

Product Application

K series reducer is a kind of gear is used to reduce the motor speed and improve the output torque of the principle of speed reducer. It uses the gear and gear meshing, with advanced design and novel structure of retarding mechanism.

• Food processing machine

• Construction machinery

• Wood processing machine

• Conveyors

• Agriculture machine

• Crane/ mineral machinery

Product Feature

Our K series helical gear reducers are based on the building block design, so its convenientfor them to fit all types of motors or to connect with other power input, and its possiblefor different types of machines to combine or connect.

• High modular design.

• Efficiency and save power.

• Save cost and low maintenance.

• Excellent sealing, wide range of industry application.

• High loading support, stable transmitting and low noise level.

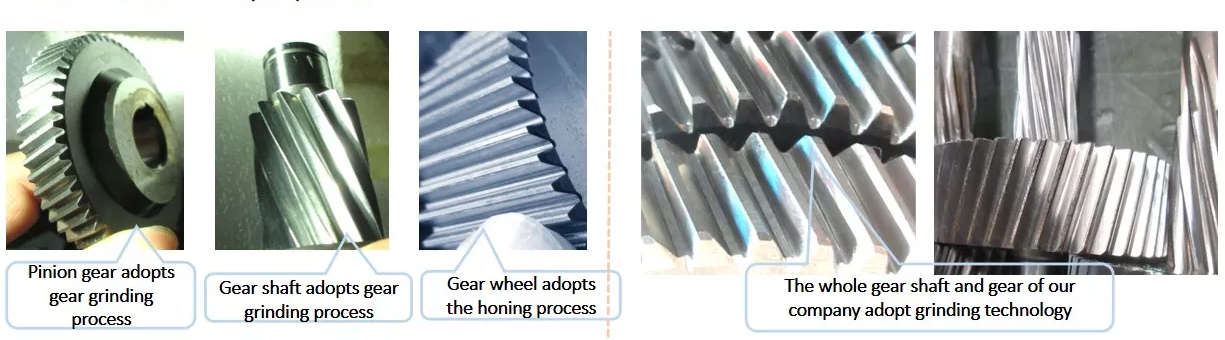

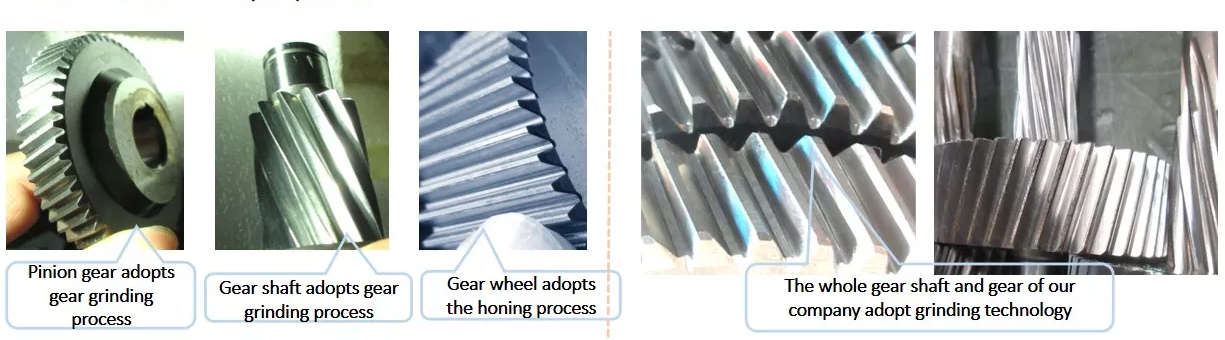

Product process

Box processing process

Mechanical modeling of metal mold → casting on production line → artificial aging treatment → shot peening → machining center processing → three-coordinate detector detection

Gear processing process

Forging → normalizing > roughing → finishing car → hobbing → tooth end chamfering → carburizing and quenching (HRC58-62) → shot blasting → grinding end face and inner hole → grinding tooth → accuracy detection (tooth shape, tooth direction, tooth Distance, level 6) → wire cutting keyway > magnetic particle inspection → ultrasonic cleaning and rust prevention

Tooth shaft machining process

Forging a normal fire and a rough car (including the center hole) a finishing car → hobbing → milling key slot → carburizing quenching (HRC58-62) a shot blasting a grinding center hole → grinding outer circle → grinding tooth → detection (tooth Shape, tooth direction, pitch, etc., level 6) → magnetic particle inspection → ultrasonic cleaning and rust prevention