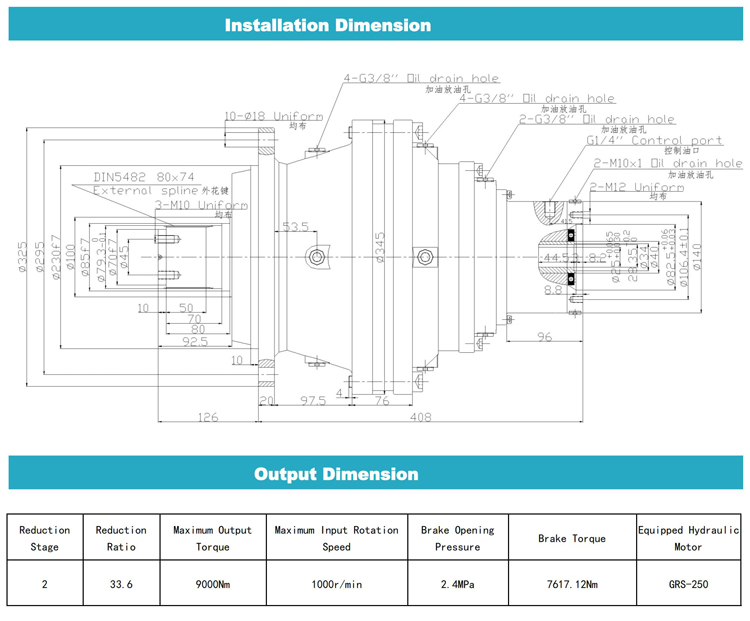

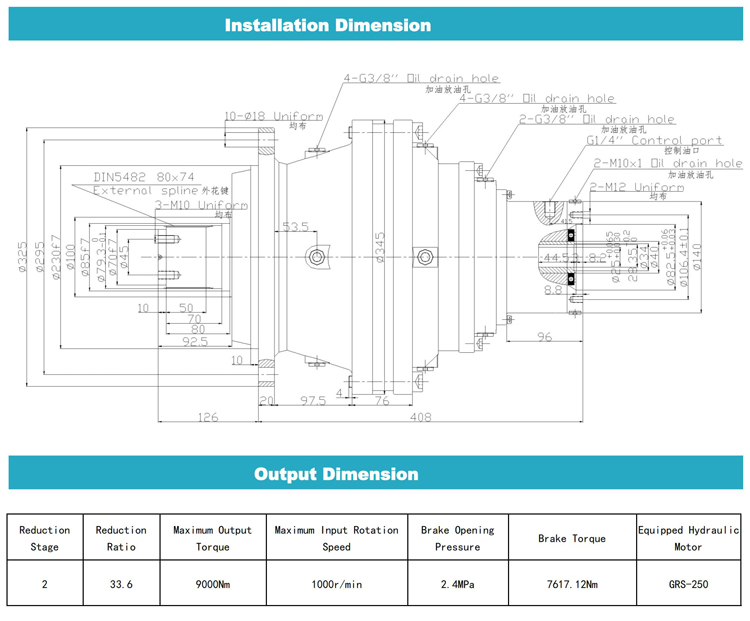

GMR Series Planetary Reducer

GMR series planetary slewing drives is a ideal speed reduce part in the rotat ing mechani sm. GMR has been broadd for the winches of the rotary drilling rig and also for the band track driving. And they could also apply to the band track hoist, amp litude winches and band track driving, many kinds of band track driving for drillig, road roller, wheels driving for aloft work, power head and move driving for the milling machine and the mine tunneling machine and also to the driving facility for shipping cranes, wharf and containers hoist.

GMR could connect with constant and variable hydraulic motors and at the same time could match the other hydraulic motors if necessary. The input end of GMR could be equipped with spring brake and the multi-plate hydraulic release parking brake according to different needs. the static braking torque of the brake goes with the hydraulic motor's input torque (generally 1.5 times bigger). According to different needs, some GMR could also be equipped with mechanically fal ling off clutch to be towed by other equipment under emergency, by which the hydraul ic components could avoid being damaged.